ROOF RESTORATION PROCESS – Step by step

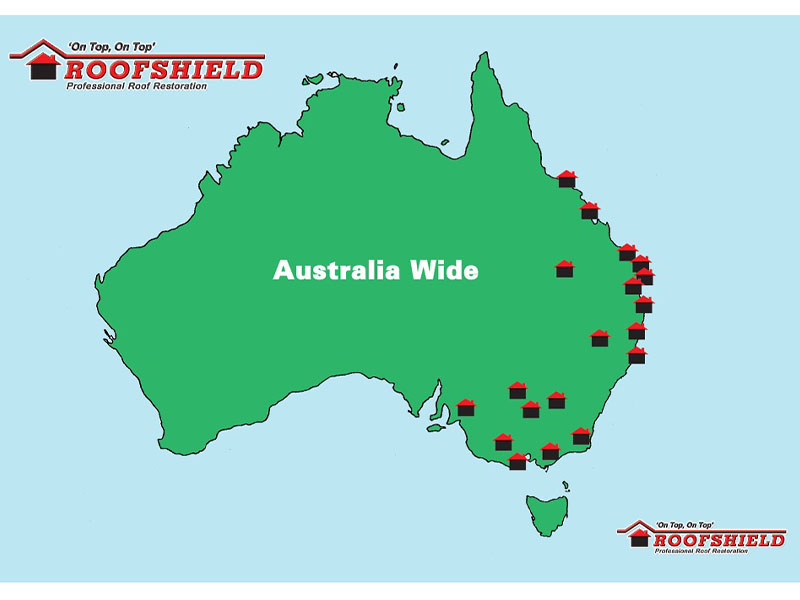

1 – Brief Introduction to Roofshield

Roofshield has been in business since 1996.

We have 17 branches along the East Coast of Australia, all independently owned.

Our Head Office in Brisbane manufactures coatings for these branches. They can use the Roofshield name as long as they follow the Roofshield Manual.

The Head Office manufactures the coatings.

We have an industrial paint chemist, Bob Gilmore, who has over 35 years of experience with Dulux and Bristol. All our raw ingredients are from Rohm and Haas, and we use raw tint to ensure color fastness.

We’ve been using the same formula Bob created in 1996 because it lasts. We haven’t changed the formula to save costs, so you know our coatings are premium.

2 – Roof preparation

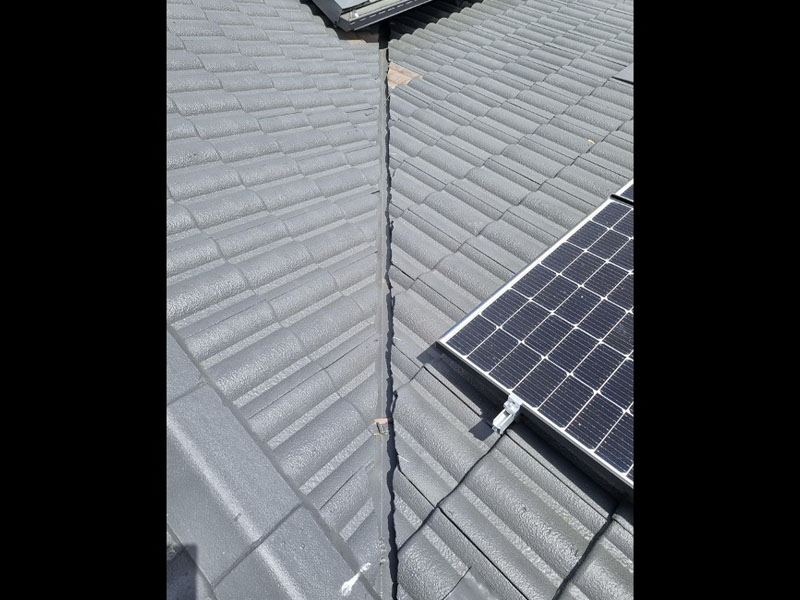

This is a ridge cap.

Because the tiles hold water, the roof will move, causing the concrete to crack and allowing water to get behind the pointing.

This erosion removes the coarse river sand from the bedding, leaving nothing for the pointing to stick to, causing it to break away.

The ridges will come loose and move out of place, failing to prevent water ingress.

These are Apex caps.

They deteriorate first due to being made of a different composite material, which disintegrates quickly from UV exposure if left unprotected.

On some roofs, the Apex is simply pointed and can leak sooner.

We find all broken and cracked tiles and replace them with the same brand and profile.

This is what we call a valley iron.

Because the tiles are halves and quarters in size, they often slip down. They also get pushed down as the roof heaves and moves from absorbing and then drying out water.

This movement causes a damming effect in your valley, especially if you have leaves from trees around your house.

We refit these and clip them into position, allowing a straight valley for water movement to your gutters.

We supply and install safety rails for high-set homes and fall areas greater than 3 meters or with a slope of 26 degrees, as per Worksafe regulations.

If you have solar panels, we can tape up and paint around them, or we can organise accredited solar professionals to remove the panels while we repair and restore underneath, then refit them after completion.

Fly-over pergolas are no obstacle.

We can clean and hand paint around the tightest areas.

We use ladder guards to protect your gutters from our ladders.

We take measures to prevent debris from falling down your downpipes during cleaning.

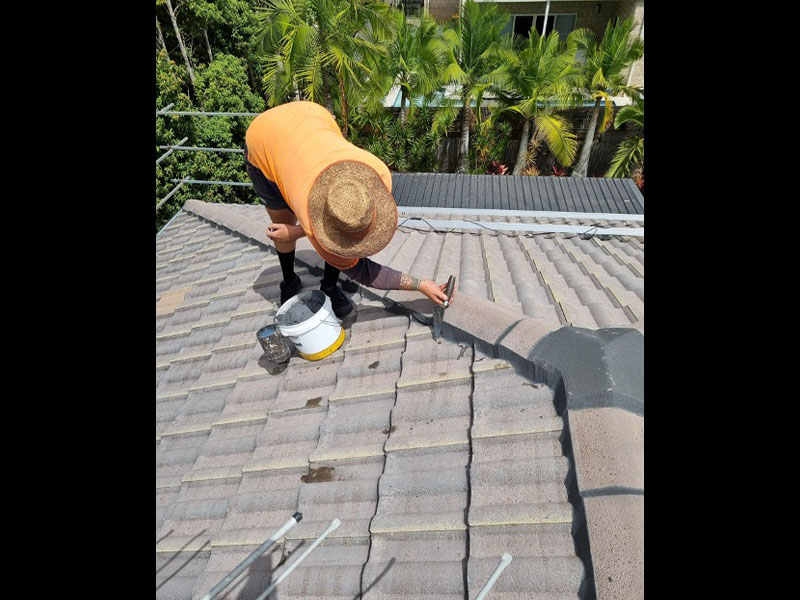

During cleaning, we use a power tip for stubborn cleaning or stripping of old coats if required.

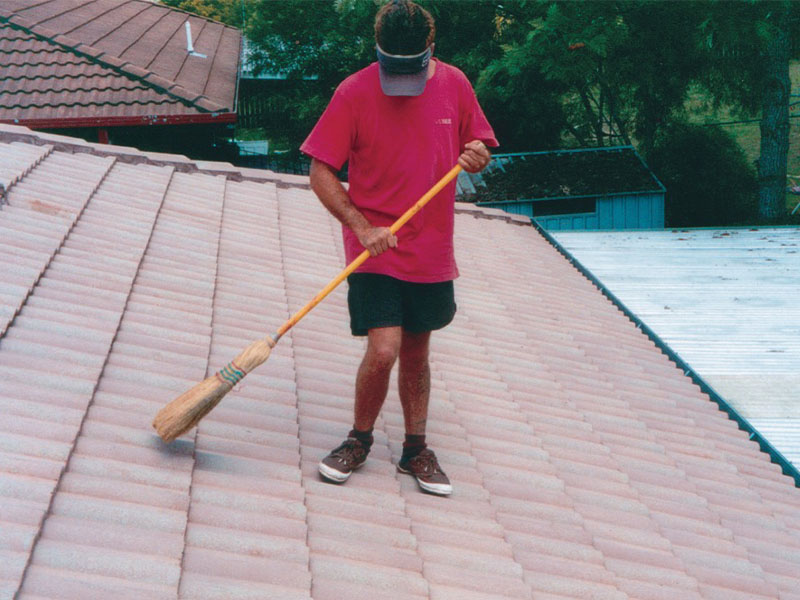

Then, we use a sweeper for large areas at 3000 psi.

This pressure removes everything required for us to achieve good adhesion for warranty without the use of chemicals or cleaning agents.

As per EPA regulations, we capture the water from cleaning at a convenient location, form a dam, and pump the water onto a grassed area or garden.

The mold and lichen from the roof help your garden and grass thrive, and the water naturally seeps into the ground, leaving behind any debris, which decomposes over time.

We repoint all ridges and hips with new modern flexible pointing, allowing 17mm of movement over 1 meter.

We remove all debris before we start coating.

3 – Roof Painting process

The first coat is our sealer/primer.

It goes on white and dries clear, sealing the porous tile surface and priming it for our top coat membrane.

The first top coat is then applied.

We apply it in a manner that allows us to coat the noses of the tiles, where they are most porous.

Then, a top coat is applied.

The barge caps are hand-painted to avoid overspray.

4 – Wrapping up

Upon completion of the top coat, you will have a nice, uniform color that will make your home look brand new.

We leave some spare painted tiles on-site for any future repairs.

Choose Roofshield Roof Restoration for Your Roof Repair

Roof Restoration Process for different types of roofs

CEMENT TILES

Cement tile roofs are a popular choice for many homeowners due to their durability, affordability, and versatility. Made from a mixture of cement, sand, and water, these tiles are known for their strength and ability to withstand various weather conditions. However, like any roofing material, they come with their own set of pros and cons, and understanding these can help homeowners make an informed decision.

TERRACOTTA TILES

Terracotta tile roofs are renowned for their distinctive aesthetic appeal, durability, and long lifespan. Made from natural clay, these tiles are fired in a kiln at high temperatures, which gives them their characteristic hard, glazed surface and rich, earthy color. This traditional roofing material has been used for centuries and continues to be a popular choice for many homeowners today.

METAL ROOF

Metal roofs are a popular choice for many homeowners due to their durability, energy efficiency, and modern aesthetic. Constructed from materials like steel, aluminum, or copper, metal roofs offer a host of benefits but also come with their own set of considerations.