Rusty Screws on a Colorbond Roof? Here’s What You Need to Know

Is your Colorbond roof just 10 years old and still in good condition, but the screws are showing signs of rust? Don’t wait until it’s too late—replace those rusty screws as soon as possible to prevent them from corroding completely and losing their hold-down strength for your metal roof sheets.

Why Replace Rusty Screws on Your Colorbond Roof?

Over time, even high-quality roofs like Colorbond can experience issues with rusty screws. These screws play a crucial role in maintaining the integrity of your roof, ensuring that the metal roofing stays securely fastened to the structure. Rusty screws can weaken and eventually fail, leading to significant problems, especially in windy conditions common in Central and North-East Queensland.

Choosing the Right Replacement Screws

The first thing you need to consider when replacing rusty screws on your Colorbond roof is the type of replacement screw you require. It’s important to select screws that match the existing holes in your metal roof sheets and battens. By reusing all existing screw holes, you minimize the need to create new holes, which reduces the risk of potential leaks and maintains the structural integrity of your roof.

When choosing replacement screws, consider the following:

- Size and Type: The replacement screws should be of the same size and type as the original ones, particularly if you’re working with timber battens. This ensures a snug fit that will hold the roof securely in place.

- Slightly Longer Screws for Better Hold: For timber battens, using screws that are slightly longer than the originals can improve the hold-down strength, particularly if the original holes have become worn or enlarged.

- Thicker Gauge for Metal Battens: If your roof is supported by metal battens, a thicker gauge screw may be necessary. This compensates for any widening of the screw holes and ensures the new screws provide the necessary grip and hold.

By carefully selecting the right replacement screws, you not only maintain the security of your Colorbond roof but also ensure that any potential leak points are effectively managed, extending the life of your roof.

Common Causes of Roof Screw Rust

- Galvanic Corrosion

Galvanic corrosion is a primary cause of roof screw rust. This occurs when different metals, such as the screw head and the surrounding steel roof, interact in the presence of moisture, particularly in coastal areas. The screw head’s rust spreads to the surrounding roof, causing delamination and further corrosion.

- Installation Damage

During installation, the torque required to fix roofing screws can damage the screw head’s protective coatings, including the paint and galvanized layers. This damage exposes the bare metal, providing an entry point for rust to develop and spread.

Key Considerations for Screw Replacement

When replacing rusty roof screws, especially on Colorbond roofs, it’s essential to consider the following factors:

1. Type of Battens: Timber vs. Metal

Timber Battens:

If your roof is supported by timber battens, you can typically replace the screws with the same size and type due to the ‘squeeze’ fit they achieve in the wood. For better results, consider using slightly longer screws—if the original screws were 50mm, replacing them with 55mm or longer screws can provide better hold.

Metal Battens:

Metal battens require a different approach. Once a screw is removed from a metal batten, the hole remains the same size. In this case, you need to use a thicker gauge screw to ensure the new screw fits securely. A metal self-tapping screw is ideal for this, as it will drill its own hole through the metal, providing the necessary hold-down strength.

3. Wind Strength Classification

The wind strength in your area, particularly in places like Brisbane and surrounding areas, dictates the spacing and strength of the screws. It’s crucial to match the existing screw type and spacing, or use stronger options if needed. A professional roofer can assess this to ensure your roof is secure against strong winds.

4. Corrosion Classification

You’re replacing those rusty screws because they’re corroding. Always choose screws with a corrosion classification of at least Class 4. For coastal areas, a Class 5 screw is recommended to prevent future rust issues. Using lower-class screws will only lead to rusting again in the near future.

5. Proper Tools and Techniques

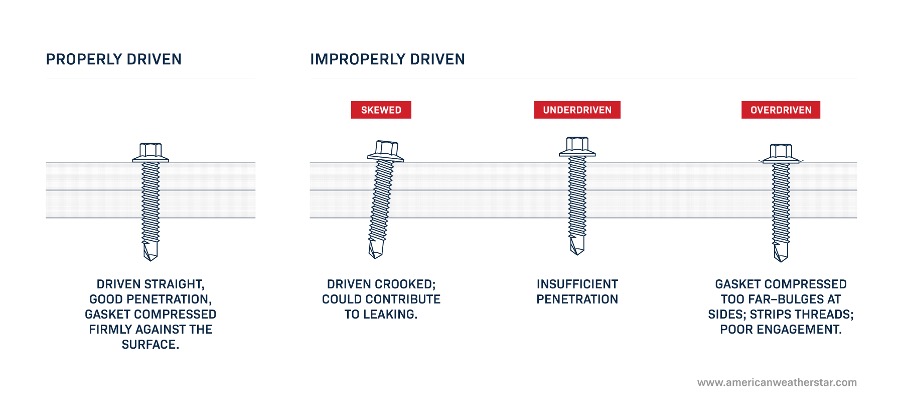

Ensure the roofer uses the correct tools. Avoid impact tech guns as they can damage the protective coating on new screws, leading to premature corrosion. An 18v drill with a clutch is ideal to prevent over-tightening.

Steps we take to Replace Rusty Screws:

- Remove Old Screws: We carefully use a pry bar or metal pipe to remove rusty screws. If the hole is damaged, we use a profile washer to cover it.

- Treat Rust: We remove rust around the screw holes using a wire brush, sandpaper, or an angle grinder. We apply a rust converter and let it dry.

- Apply Galvanized Paint: Once the rust treatment is dry, we apply two coats of galvanized paint to protect the metal.

- Install New Screws: We place the rubber washer or profile washer, and new screw into the hole. We also consider adding a bead of sealant around larger holes for extra protection for extreme cases.

6. Safety and Professional Help

Replacing rusty screws, especially on metal roofs, can be dangerous. Working at heights carries risks, so always engage a professional with public indemnity insurance. This ensures that any accidents are covered, protecting you from potential liabilities.

Extend the Life of Your Roof

If your roof is showing signs of age and corrosion, it might be the right time to pair screw replacement with a protective coating membrane. This can enrich the color of your roof or even give it a modern new look. At Roofshield, we offer comprehensive services that not only replace rusty screws but also protect your entire roof, extending its life and adding value to your home.

Benefits of Roofshield’s Services:

- Complete Rusted Screw Removal

- Application of Protective Coating

- 10-Year Warranty on Workmanship

In Brisbane and throughout Queensland, protecting your Colorbond roof from rust and corrosion is essential to maintaining the longevity of your steel roof sheets. Contact us today to ensure your roof remains secure and looks great for years to come.